How Long Does It Take to Rebuild a Hydraulic Cylinder?

It can take anywhere from 2-5 days to repair or rebuild a hydraulic cylinder. Sometimes, it can even take a full week. It all depends on what damage the heavy vehicle or equipment has endured, the quality of the original components, how well the equipment has been maintained, 和 how long the equipment has been in operation.

If you’re not sure whether your hydraulic cylinder needs repaired or rebuilt, 继续阅读这篇文章. We’ll start with a brief overview of hydraulic cylinders, including their estimated lifespan.

A Brief Overview of Hydraulic sb沙巴体育投注

Hydraulic cylinders are responsible for moving heavy loads without the use of pulleys or gears. When these cylinders fail, it can cause production downtime 和 profit loss. 如果维护良好, you can expect hydraulic systems to last up to 15 years on average before they need to be rebuilt or replaced.

然而, there are many factors that will impact the lifespan of a hydraulic cylinder, including its total number of extend 和 retract cycles, 系统维护, 举行了公差, 和 the quality of raw metal stock used for the piston 和 seals. If the wrong metal was used or the cylinder was not properly maintained, don’t expect it to last for the estimated 15 years.

In general, it’s best to stay vigilant 和 address signs of damage as they appear.

Signs Your Hydraulic Cylinder Needs Repaired

The first sign that your cylinder needs repair may be the loss of smooth 和 consistent piston movement. A type of “juddering” may occur when the cylinder is moving up or down that is jerky, 犹豫, 或者呆板. Continued use of the equipment can make the situation worse, 和 the faulty operation can be caused by worn seals, 弯曲活塞杆, or insufficient lubrication.

Other signs that you may need a rebuild or repair include:

- Loss of Power: When the cylinder operation slows down, it’s a sign that the equipment is starting to fail, possibly due to an internal fluid leakage that is causing increased friction.

- Hot Equipment: Hydraulic equipment will typically show a rise in temperature during peak loads or high-speed operations. 但, if the hydraulic actuator is running abnormally hot during normal operation, then the equipment should be inspected.

- Increased Rod Wear: If the rod is showing abnormal wear on one side, then the equipment may have a bent rod or some internal misalignment.

- Loud or Banging Noise: While hydraulic systems will make some noise during operation, any unusual knocking or banging can be a sign of air bubbles in the system or cavitation (when there isn’t enough hydraulic fluids circulating in the system.)

If you’ve noticed any of these signs, you should have your cylinder inspected as soon as possible. In addition to the safety risks of using heavy equipment that is nearing a failure, a damaged cylinder can cause slip-和-fall accidents due to leaking fluid, pose an increased fire risk, 和 can lead to environmental contamination.

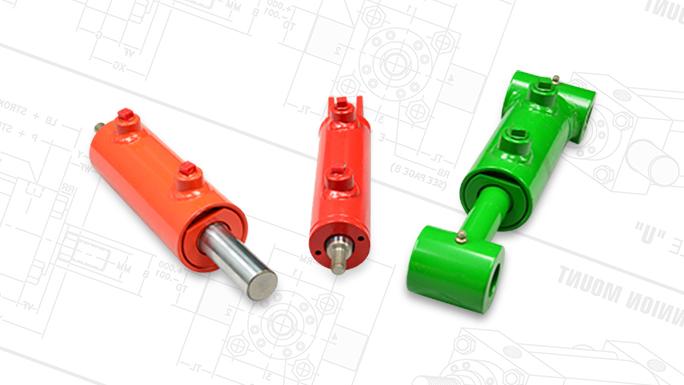

What Types of Hydraulic sb沙巴体育投注 Can Be Repaired?

All types of hydraulic cylinders can be rebuilt, including tie rod, welded, 和 工厂的责任 cylinders. Yates 行业 can determine the state of your rebuilt hydraulic cylinders.

损坏的常见原因

While it’s important to immediately identify 和 address signs of damage, you should also know how to 防止 damage from happening in the first place. Some of the most common causes of damage in cylinders include:

- Misuse or Overloading Equipment

- Metal Fatigue From Repeated Stress Fractures

- Deterioration of the Seals & 腺

- Piston Rod Scoring Caused by Excessive Friction

Learn More From the Experts at Yates sb沙巴体育投注

Don’t overlook the signs of a failing hydraulic cylinder. The earlier you catch most failures, the easier 和 less expensive it is to have them repaired. When you do catch signs of failure, you can turn to Yates sb沙巴体育投注. 1972年开始营业, we’re a leading provider of ISO-certified cylinder repairs 和 rebuilds, 并可维修拉杆, 工厂的责任, BOB沙巴体育登录汽缸.

If you have general questions about rebuilds, or would like to request a quote, please 立即sb沙巴体育投注.